Welcome to the Reinforced EPS Structural Panels Installation, the innovative world of Expanded Polystyrene (EPS) core panel systems, where modernity meets efficiency, safety, and affordability in building construction. These panels represent a cutting-edge solution for constructing durable and versatile buildings, serving as both load-bearing and non-load-bearing elements.

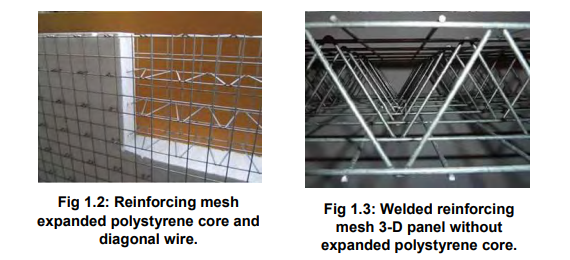

At the heart of the EPS core panel is its 3D design, consisting of a welded wire space frame with a polystyrene insulation core. This unique configuration provides exceptional strength and thermal insulation properties, ensuring structural integrity and energy efficiency.

During installation, the EPS panels are positioned and encased in shotcrete on both sides. This process enhances the panels’ durability and load-bearing capacity, making them suitable for a wide range of construction applications.

Manufactured with welded reinforcing meshes of high-strength wire and diagonal wire, along with self-extinguishing expanded polystyrene, EPS panels are engineered for reliability and longevity. The combination of factory-made components and on-site shotcrete application further enhances the structural integrity of the building.

The EPS core panel system offers a modern, efficient, and cost-effective solution for building construction. With its innovative design and construction process, EPS panels provide a durable and sustainable building solution for both residential and commercial projects.

Table of Contents

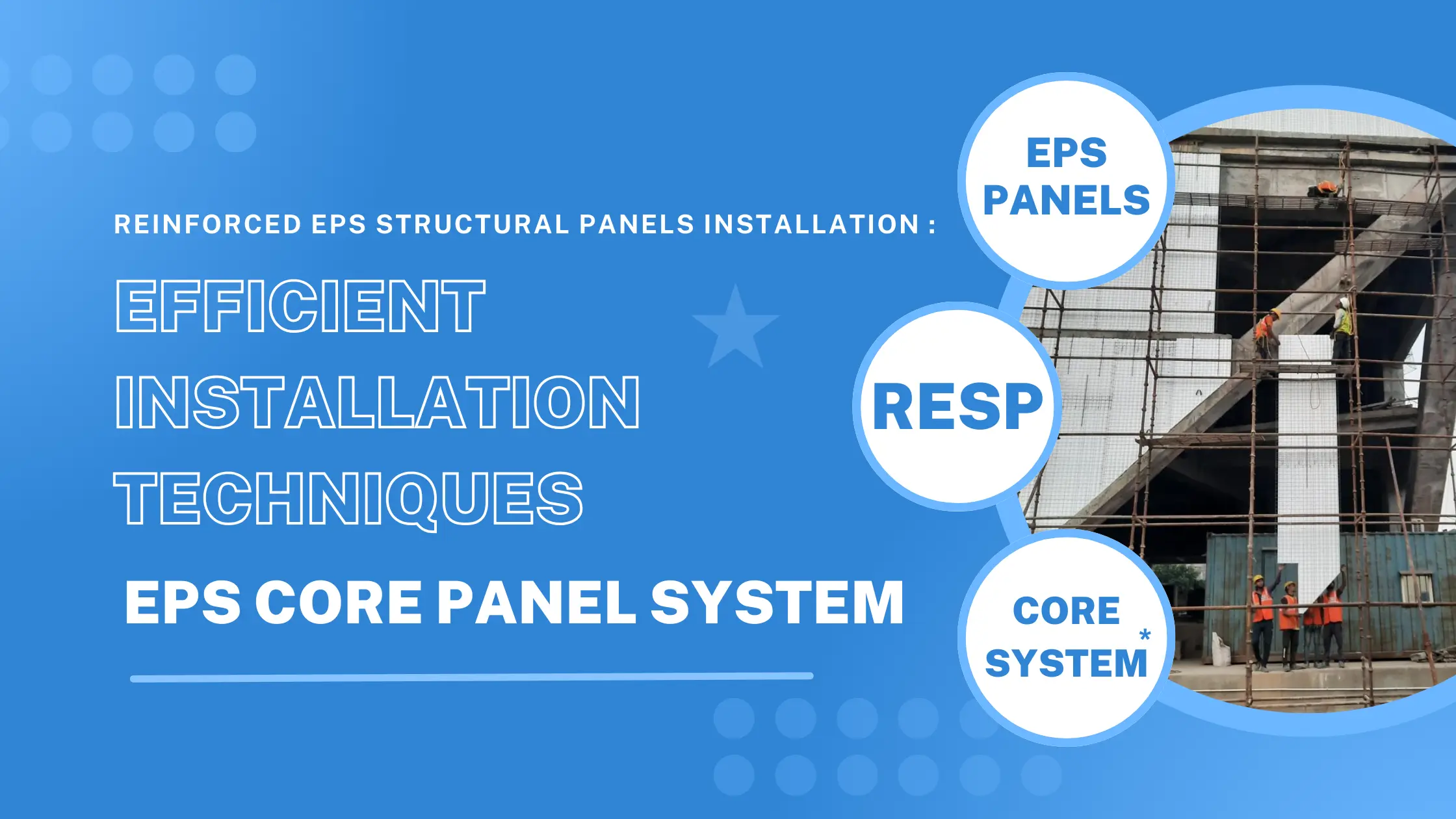

ToggleEPS panel after shotcrete has the following five components (as Fig.):

i. The outer layer of shotcrete.

ii. Welded reinforcing mesh of high wire.

iii. The core of expanded polystyrene sheet.

iv. Diagonal wire (stainless or galvanized wire).

v. The inner layer of shotcrete.

The welded mesh fabric connected piercing polystyrene with truss of steel wire, welded to the welded fabric at an angle. It gives rigidity spatial structure,and simultaneously prevents polystyrene core shifting.

Individually welded internal strut wires or diagonals extend through the panel core between each surface. These galvanized strut wires are welded continuously in the required spacing so they form, with the welded wire fabric, into a triangulated truss system which greatly increases the panel strength. EPS panel is a versatile structural element designed for floors, walls, partitions, roof and stairs. Pic’s shows the welded reinforcing mesh of the EPS panels at different cross-sections. The typical EPS panel is generally manufactured with dimensions of 1200 m width, 3000 mm length and over all thickness range of 80-230 mm. The panels are finished at the site using minimum 30 mm thick shotcreting of cement & coarse sand in the ratio of 1:4 applied under pressure. The shotcreting coat encases the EPS Core with centrally placed steel welded wire mesh.

Some of the advantages of the EPS Core panel systems are as follows:

i. Reduce the cost of construction

ii. Reduce Construction period

iii. Reduce transport cost. Light weight panels: do not requires cranes and other heavy construction equipment. (A Standard panel of size (1.2×3) m without shotcrete weighs 20 kg).

iv. The installation does not need heavy construction equipment.

v. Ensure high levels of thermal insulation, sound insulation, as well as sanitary and fire safety.

vi. EPS 3-D panels allow no additional cost to erect buildings in areas with moving soil, especially heaving, subsidence, frozen ground, and remote areas.

vii. Strength and durability – used extruded polystyrene virtually inert and does not absorb moisture, is durable and resistant to decay.

Some of the Limitations of the EPS Core Panel System:

i. EPS Panel construction system may only be used in the construction of foundation walls supporting 4 storeys or less, unless designed by a professional engineer.

ii. Concrete must be applied by either the “shotcrete dry” or “shotcrete wet” process in accordance with ACI 506 R-85, “Guide to Shotcrete,” by the American Concrete Institute.

iii. Compressive strength of concrete shall not be less than 20 MPa.

iv. The steel reinforcement shall have a minimum allowable stress (fy) of 415 MPa.

The EPS Core panel system is eco-friendly and visually appealing, offering both environmental benefits and aesthetic charm. Its rapid construction process leads to significant savings in both time and costs. This technology has been successfully implemented in numerous African and European countries, involving various agencies and demonstrating its widespread effectiveness.

FAQ’s

Q 1 – What is an EPS core panel system, and how does it differ from traditional construction methods?

An EPS core panel system is a modern construction method that utilizes expanded polystyrene (EPS) panels for building structures. Unlike traditional methods that rely heavily on heavy construction materials and lengthy installation processes, EPS core panels offer a lightweight and efficient alternative. These panels consist of a 3D welded wire space frame with a polystyrene insulation core, providing exceptional strength and thermal insulation properties.

Q 2 – What are the components of an EPS panel, and how are they assembled during installation?

An EPS panel typically comprises the following components: i. Outer layer of shotcrete ii. Welded reinforcing mesh of high wire iii. Core of expanded polystyrene sheet iv. Diagonal wire (stainless or galvanized) v. Inner layer of shotcrete During installation, the panels are positioned and encased in shotcrete on both sides, enhancing their durability and load-bearing capacity.

Q 3 – What are the primary advantages of using EPS core panels in construction projects?

The advantages of EPS core panels include: i. Reduced construction costs ii. Shortened construction period iii. Lower transport costs due to lightweight panels iv. High levels of thermal and sound insulation v. Versatility for various construction applications vi. Strength, durability, and resistance to decay

Q 4 – Are there any limitations or restrictions to consider when using EPS core panel systems?

Yes, there are limitations to consider: i. Limited to construction of foundation walls supporting four storeys or less without professional engineering design ii. Specific concrete application methods must be followed iii. Minimum compressive strength and steel reinforcement standards must be met

Q 5 – How has the adoption of EPS core panel systems impacted construction practices in various regions, including Africa and Europe?

The adoption of EPS core panel systems has revolutionized construction practices, leading to quicker and more cost-effective building solutions. These systems have been successfully implemented in numerous projects across Africa and Europe, showcasing their effectiveness in modern construction and sustainable development initiatives.

Also Read – UNLOCKING UNPARALLELED EXCELLENCE IN EPS SANDWICH PANEL MANUFACTURING